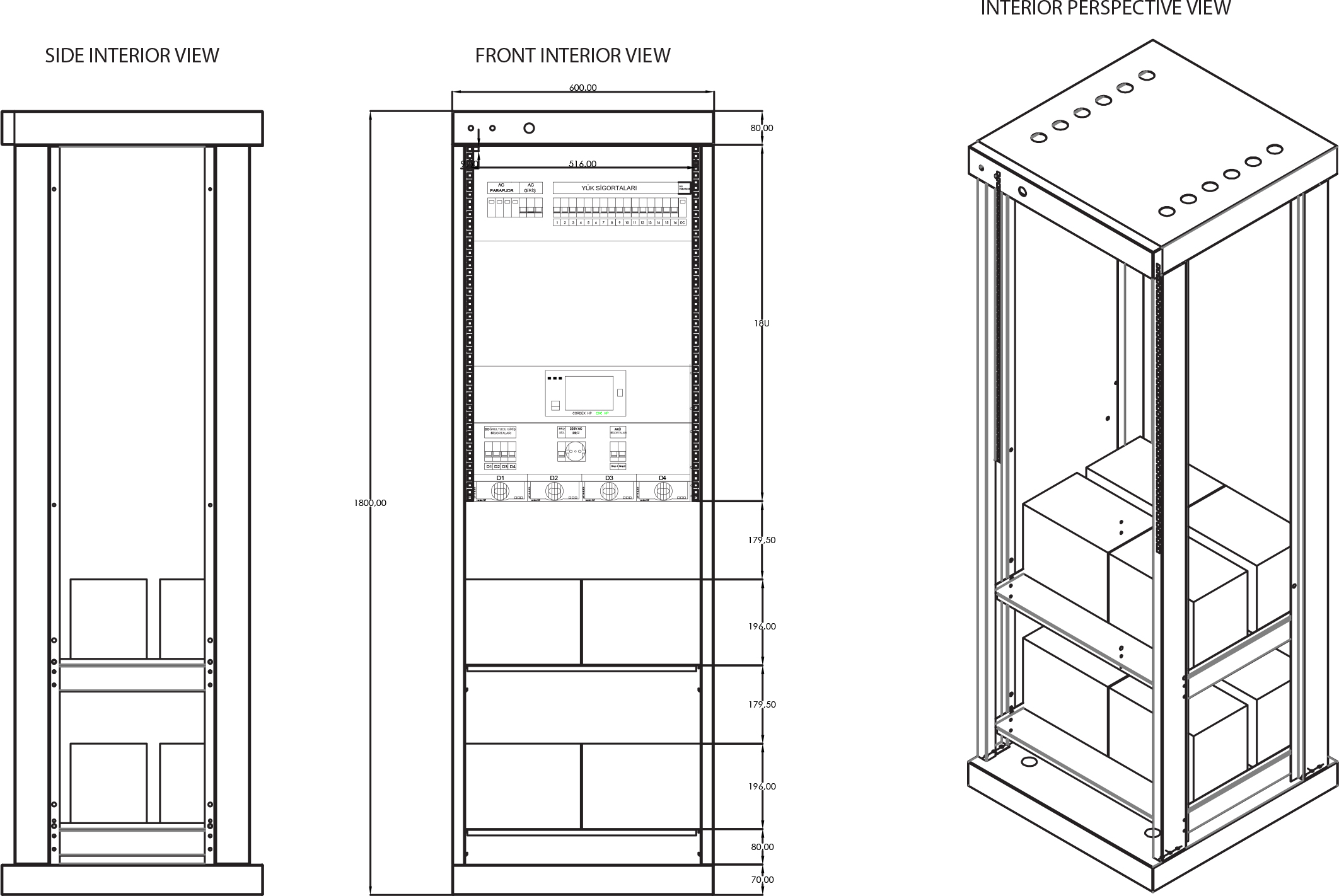

The Tescom DC Power Supply System rectifies single-phase AC grid voltage to 53.5V DC (nominal 48V DC), offering capacities of 6KW-48V and 48KW-48V. It simultaneously maintains backup energy with battery banks in float charge mode while powering critical loads.

The Tescom DC Power Supply System rectifies single-phase AC grid voltage to 53.5V DC (nominal 48V DC), offering capacities of 6KW-48V and 48KW-48V. It simultaneously maintains backup energy with battery banks in float charge mode while powering critical loads.

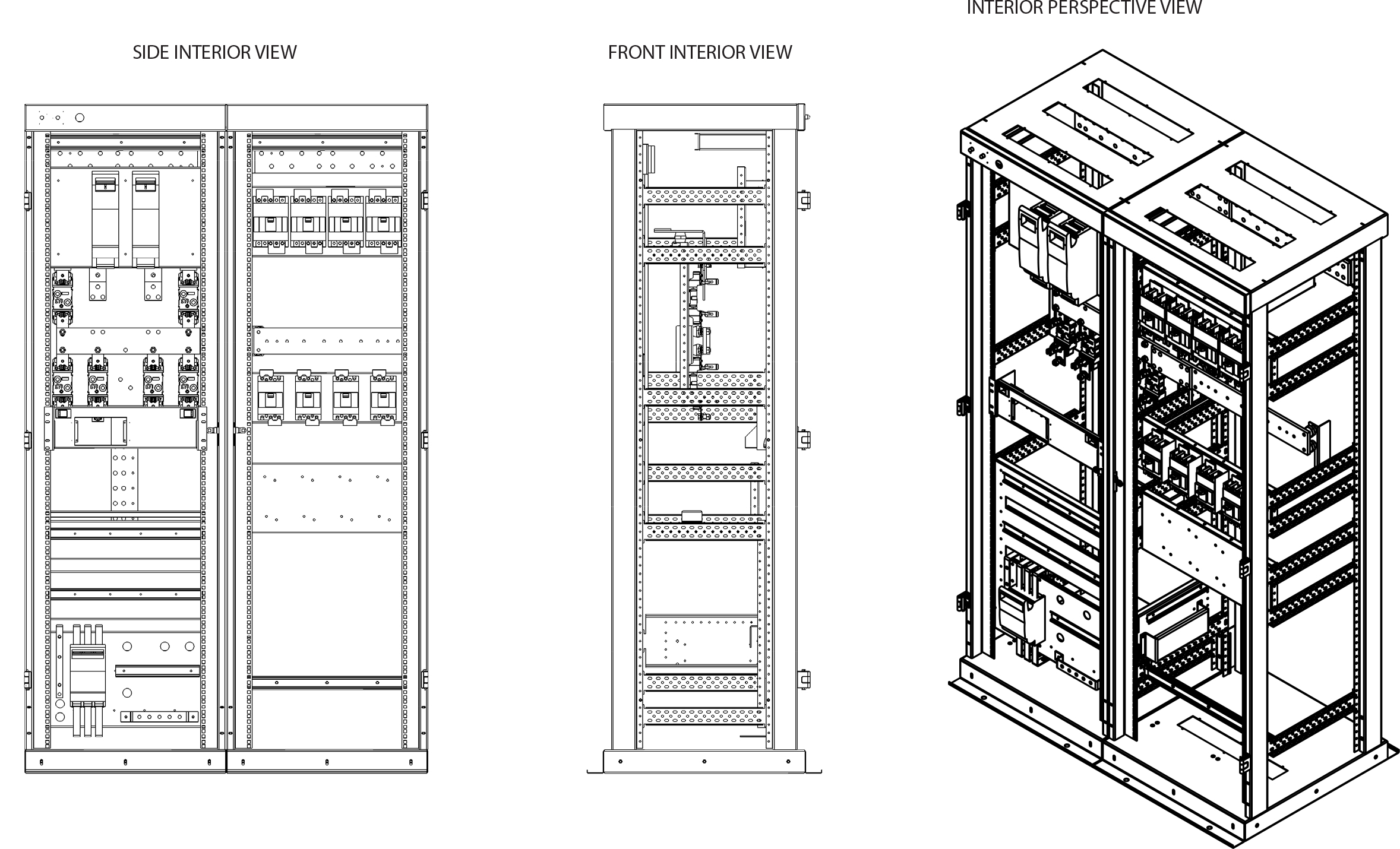

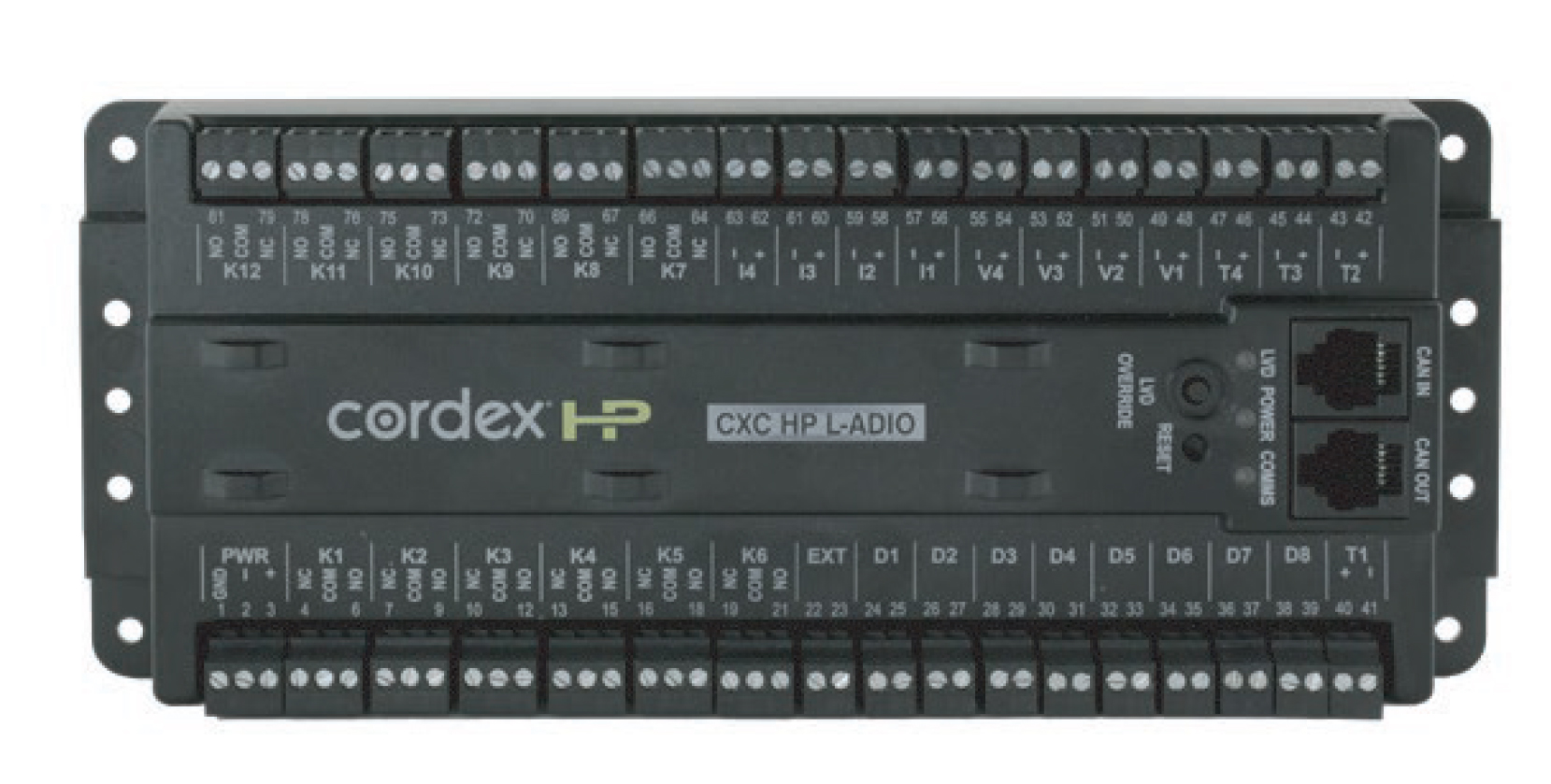

The DC system comprises 48V-3KW Cordex rectifier modules for N+1 redundant operation, a CXC HP Cordex control unit, fuse monitoring card (for battery, AC, and DC distribution), main AC and rectifier input fuses, surge protection devices, battery and load fuses, as well as alarm, load, and battery connection terminals.

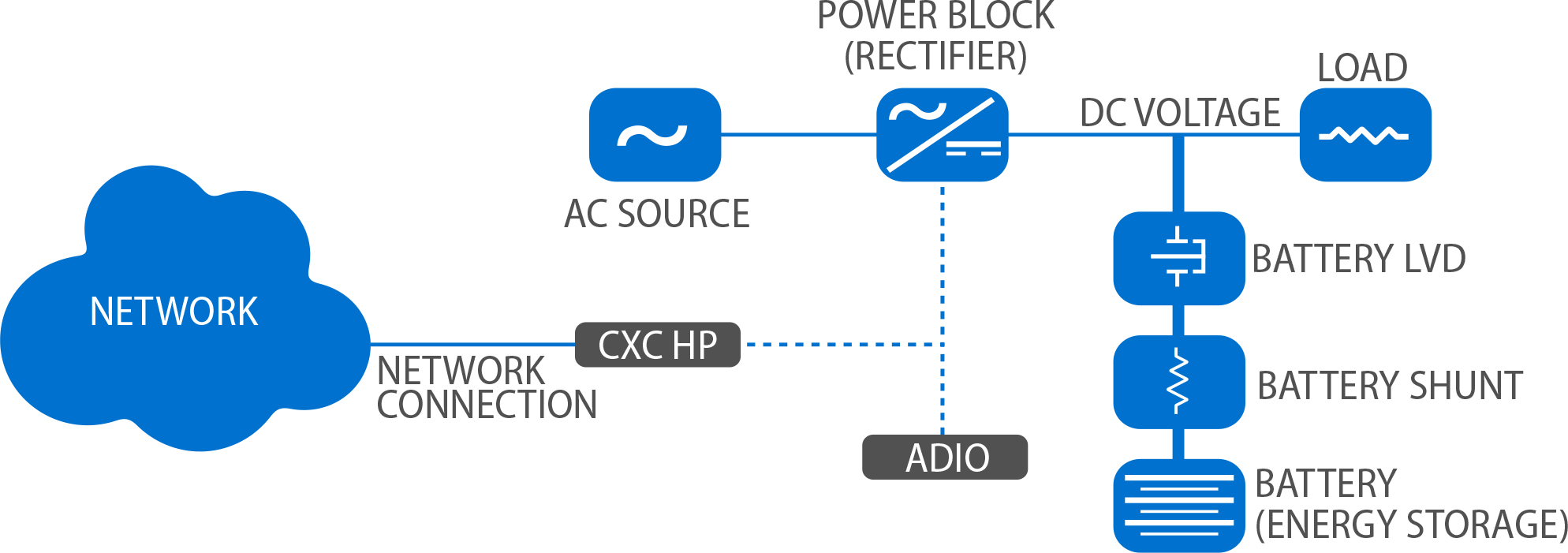

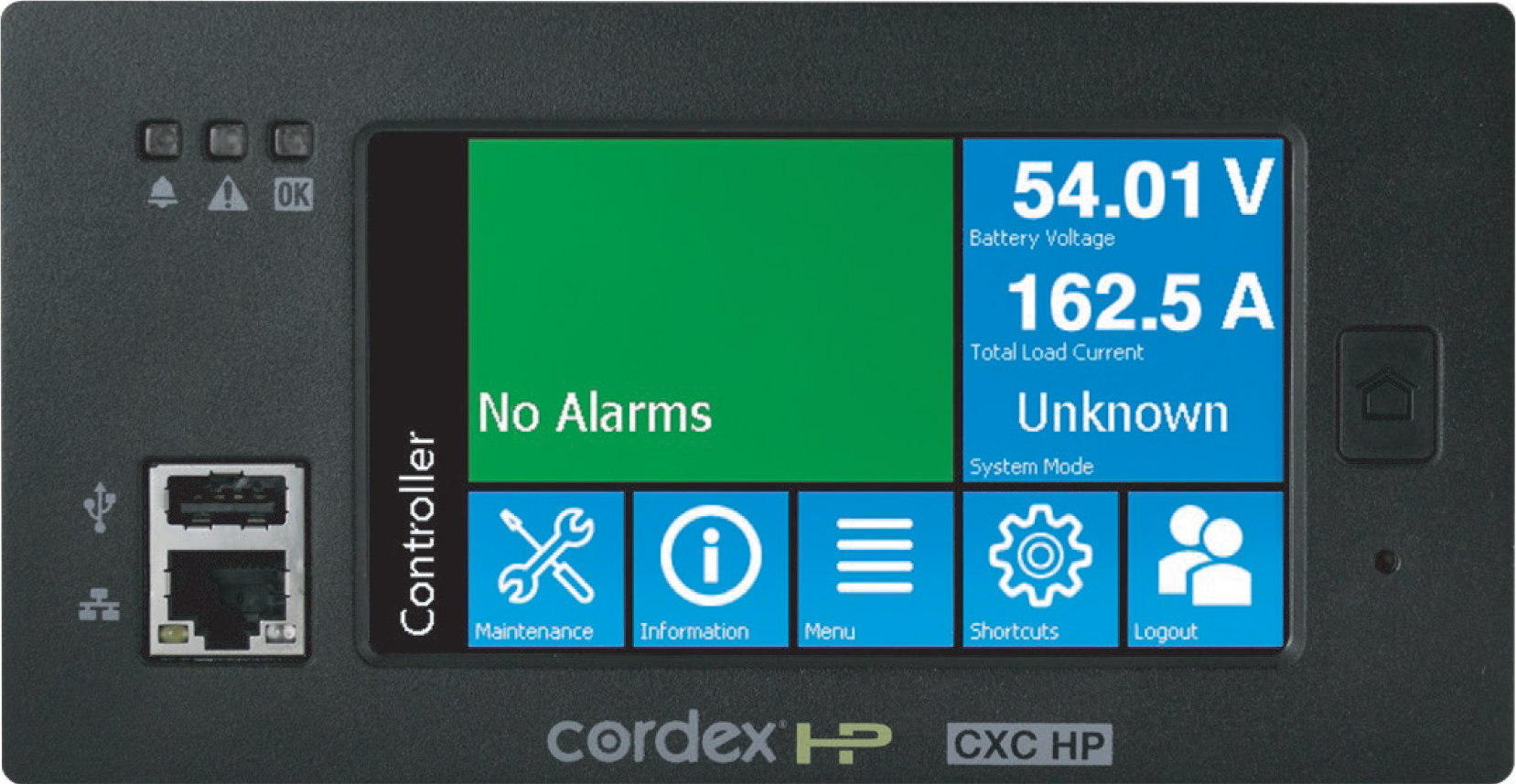

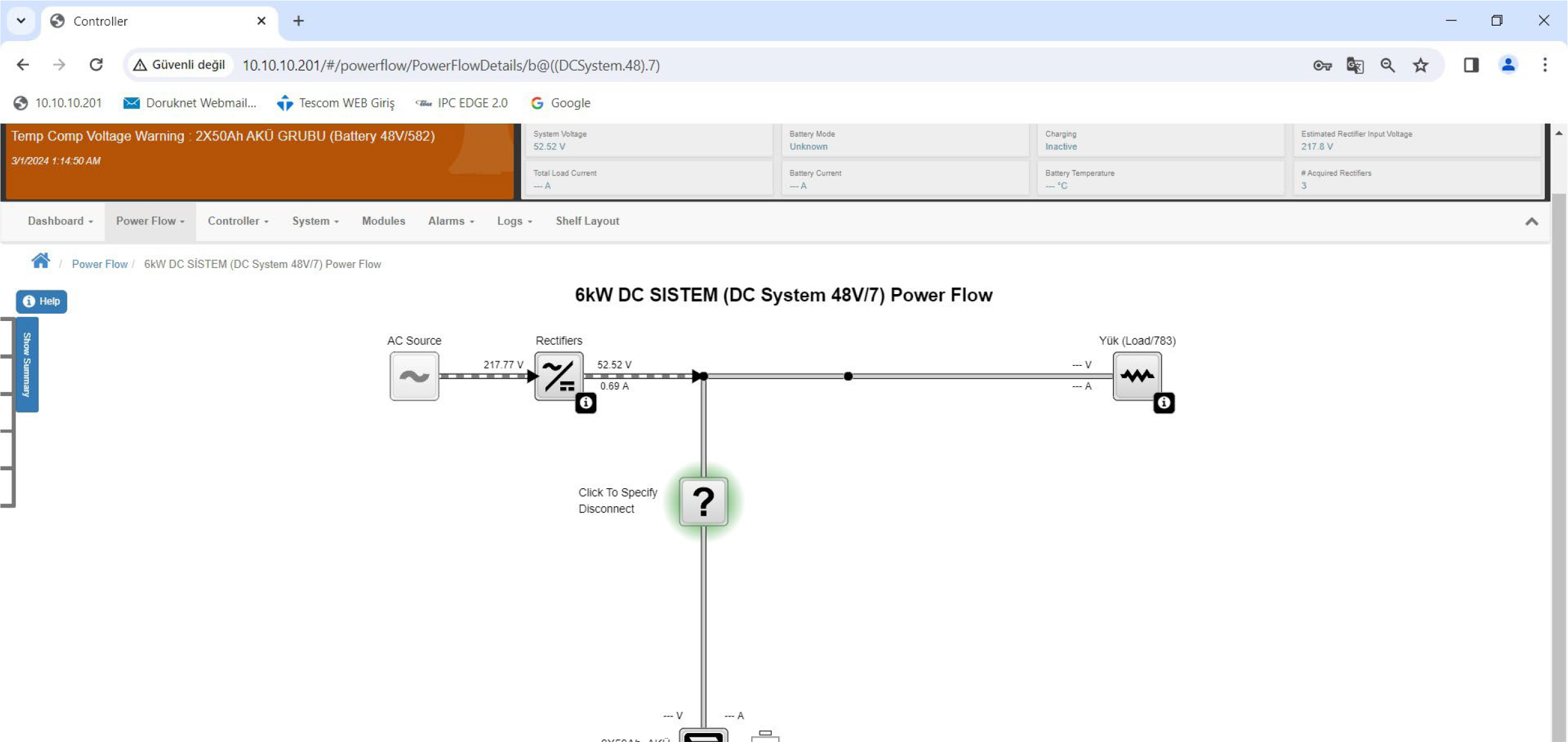

The Cordex® CXC HP Controller is a scalable software platform that allows the creation and management of multiple systems by a single controller. The user interface is organized around the system inventory, enabling visibility and independent management of the systems you create. Both the web interface and LCD provide a summary of controller and alarm information, as well as an overview of all systems monitored by the controller.

The specific example of a DC power system with the indicated sub-components is illustrated below:

The Cordex 48-3kW Rectifier Module employs a regulated technique that provides conversion in high-frequency switching mode and isolates the AC input from the DC output. The rectifier power modules operate on the principle of “hot-swappable,” allowing modules to be removed and replaced without interrupting system power. The rectifier input is compatible with 208/220/240 VAC 50/60 Hz grid.

A complete Cordex rectifier system consists of one or more rectifiers and a rack chassis. The chassis includes AC and DC power connections as well as communication ports.

The Rectifier Shelf system is designed to work with the Alpha Cordex System Control Unit (CXC). Through the CXC, users have access to all the settings, control, and monitoring capabilities of the Power System.

CXC (Control Unit) is mounted on the same shelf as the rectifier modules and provides advanced monitoring capabilities. This Control Unit allows for full control of DC Power Systems, with all features of Cordex software being loaded onto it.

At the rear of the front panel of the CXC, there is a microprocessor-based main board.

The CXC facilitates easy monitoring and adjustment of DC systems through a web server using standard Windows Internet Explorer browser.

The data logging feature enables users to capture data from multiple inputs such as AC/DC voltages, load/battery voltages, cell voltages, and temperatures. Typical applications of CXC include recording operational details of DC power systems, thermal performance of outdoor cabinets, battery cell characteristics, and logging grid changes (AC voltage watchdog).

Audible alarms for generated alerts are provided through an integrated buzzer in the module.

Terminal connections are available on the Input/Output (I/O) card located at the rear of the shelf.

The three LEDs on the front panel allow for obtaining information regarding system startup, file transfer, alarms, and testing.

The features available on the controller are as follows:

The L-ADIO is a standard analog and digital I/O peripheral for low-voltage (<60Vdc) systems. It communicates with the controller via the CAN bus and provides user access to I/O management through the CXC HP controller.

The L-ADIO offers voltage, current, and temperature inputs for various voltage monitoring requirements.

The control panel is the default view displayed when you log in to the controller via the web interface. It provides a current overview of the most critical information in your system. It displays controller information, a system summary table, and a list of active alarms.

| Name | File Size | ||

|---|---|---|---|

| 1) | DC POWER SUPPLY SYSTEM (6kW / 48kW - 48V) |